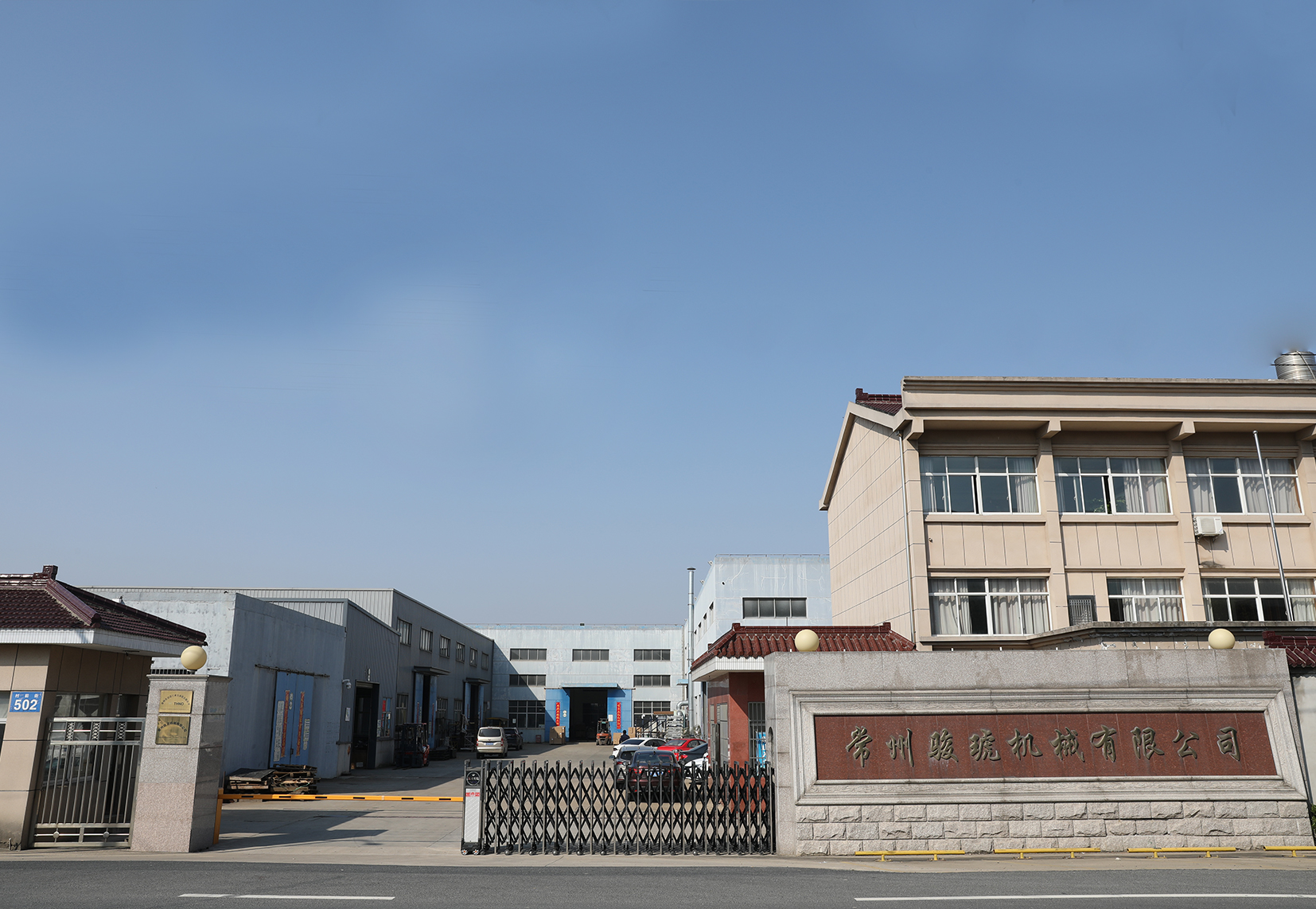

Changzhou Junhu Machinery Co., Ltd créée en 2002, est un professionnel Chine Vente en gros Fabricants d'armoires en tôle et Usine de moulage sous pression en métal, engagé dans la recherche, le développement, la production, la vente et le service de fabrication de tôles, de pièces d'emboutissage, de pièces structurelles de machines de construction, de base de générateur, de pièces métalliques personnalisées et de boîtiers/boîtiers d'appareils intelligents, avec certification ISO9001. Nous sommes situés dans la ville de Changzhou, qui est très proche du port de Shanghai. Notre usine couvre plus de 14 000 mètres carrés, équipée de près de 110 employés et plus de 25 % de techniciens, dédiés à un contrôle de qualité strict et à un service client attentionné. Notre société a introduit une série d'équipements de pointe, notamment une machine de découpe laser, une machine de découpe de plaques CNC, une poinçonneuse, des cintreuses CNC et des lignes de revêtement et d'assemblage en poudre. nos produits se vendent bien en Chine et sont également exportés vers l'Australie, l'Italie et le Canada, etc. Les commandes OEM et ODM sont également les bienvenues. Nous pouvons personnaliser les produits métalliques pour vous selon les dessins ou les échantillons.

Caractéristiques du produit: 1. Cadre d'établi solide pouvant charger 1 000 kg ; 2. Un...